26

lances. Then we inject the iron-rich water. In

the future, we will be using several rows of

lances that will move along canals or roads

like a roller with the aim of installing a large

sheet of bog iron beneath the surface.’

Rolling in the deep

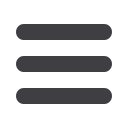

Then it was time to prove that the idea

actually worked on a large scale. The team

of researchers tested the 'roller' in a trial

with three tons of injection material in a

2.5-metre-deep, 40-square-metre container

in the laboratory in Delft. The engineering

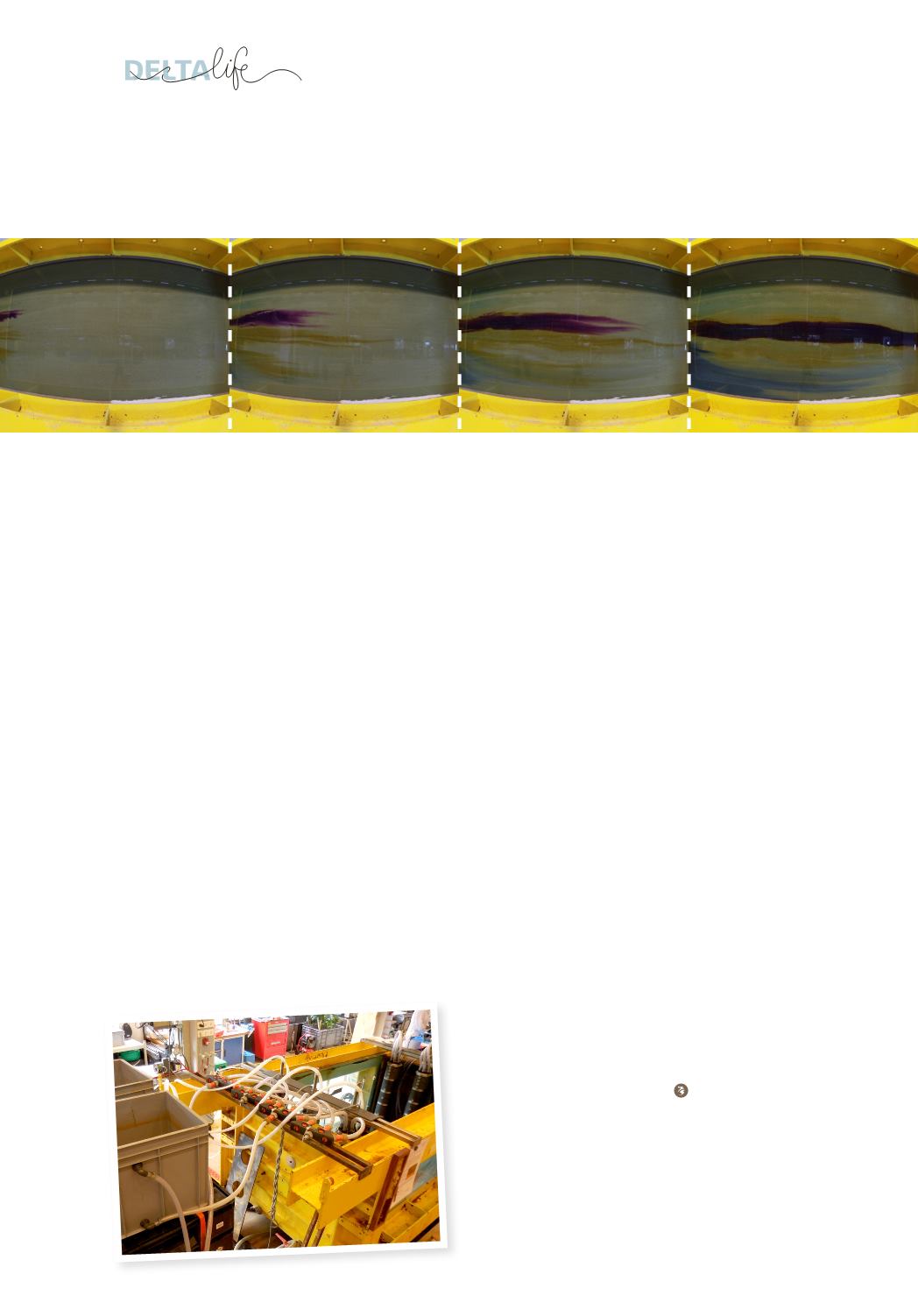

firm Hektec designed a special plant for

making the mixtures and injecting the right

amounts into the ground.

There was also an opportunity to conduct

tests in natural conditions when a pond

had to be enlarged in the Veluwe area of the

Netherlands. The researchers wanted to

show that you can do this by extending the

impermeable layer below the pond using bog

iron.

Those experiments identified a new

challenge: you can’t, of course, see anything

below the ground. Marco de Kleine and

his team therefore designed a monitoring

system to watch the injection of bog iron.

‘We can now pinpoint the location and the

spread of the new bog iron. So we know

immediately whether the job has been done

right.’

Application

The team is now waiting to put the idea into

practice. There are numerous possibilities.

Flows of groundwater into construction pits

can be reduced. Bog iron can also be used

to deepen canals and roads. Injecting bog

iron is more environmentally friendly than

sodium silicate and water glass and it may,

depending on the situation, be significantly

cheaper than traditional sheet piling.

Wim de Lange gives an example: ‘Let's say

a canal has to be made wider and deeper

to accommodate larger and taller ships. If

you don't want to replace all the bridges,

you have to lower the water level. But then

the groundwater level will be lower on either

side of the canal. Homes and nature areas

alongside may subside or dry up and that is

certainly not a good idea. We think bog iron

could be a great option here.’

More information:

wim.delange@deltares.nlThe development of bog iron in the test set-up.