21

that rubbish would accumulate in

them.’

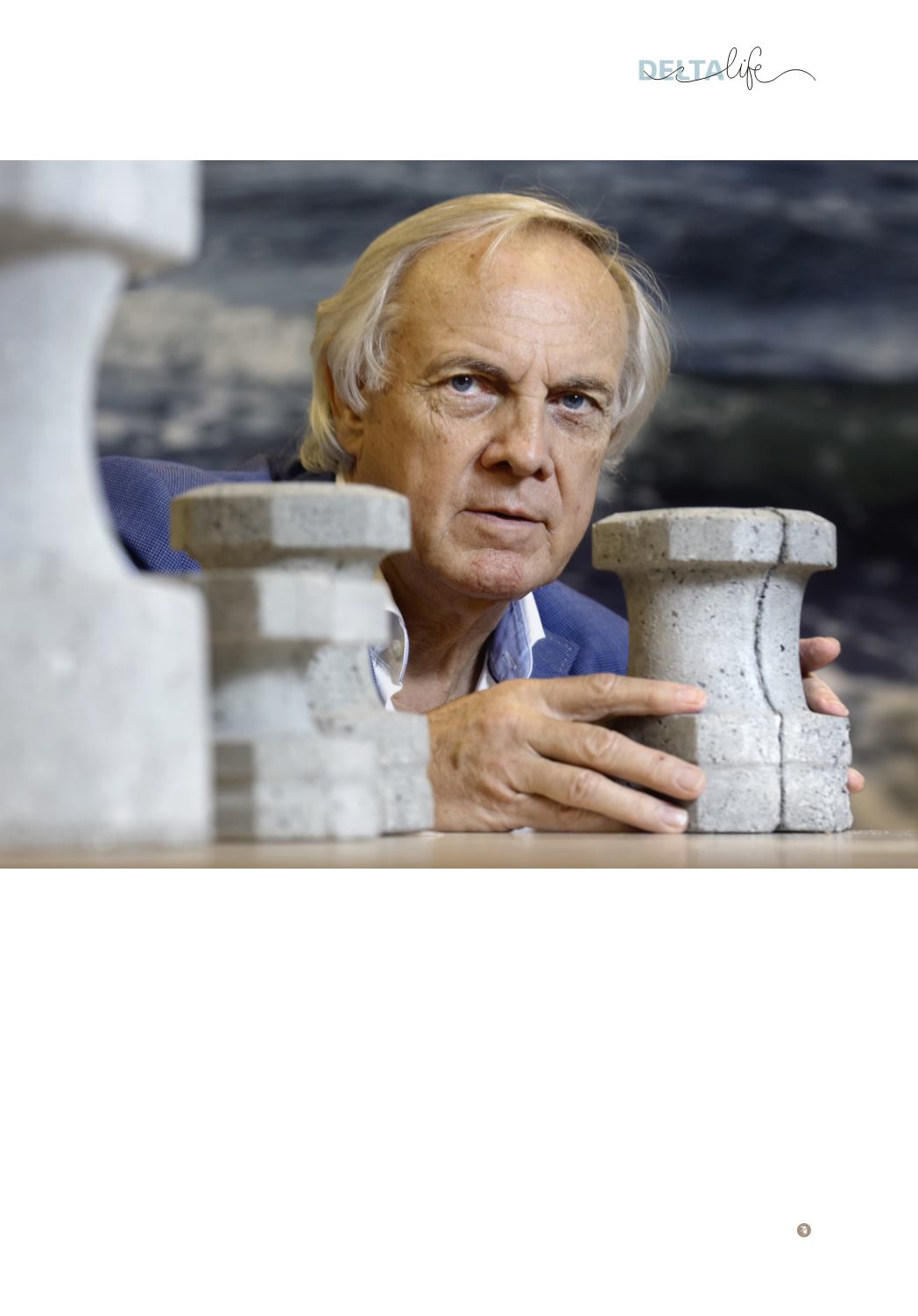

Wanted: concrete manufacturer

Hans Hill went looking for a concrete

manufacturer. ‘It was still difficult to

find a good factory that was prepared

to take on a new block.’ It was only

when Martens Beton agreed to make his

block that he had something to show

customers. And then things went fast.

After tests in the old Delta Flume at

Deltares and a pilot project in the

Stavenissepolder, it was possible to

perfect the Hill Block. ‘Normally, it is

not the force of the waves that degrades

dike revetments; the problem is the

suction forces when water gets into the

hollow spaces between the blocks. If the

openings are too small, the water rips

the blocks off the dike.’

Rijkswaterstaat, the Dutch govern-

ment agency that is responsible for the

dikes, was enthusiastic about Hans

Hill's invention. They wanted to see

whether it could be useful in Dutch dike

construction and they commissioned

a large-scale study of new and existing

dike-revetment blocks in the new Delta

Flume.

There is also increasing interest abroad

in the Hill Block. ‘But at the moment

we have more than enough to do in the

Netherlands.’

Family company

Alongside Hans Hill, the Hill Block team

now includes four people, including his

wife and daughter. They work from an

office on the 19th floor of the World

Trade Centre in Rotterdam. While con-

tinuing his work as an inventor, Hans

Hill hasn't entirely given up on his old

job of making photographs and films. ‘I

still go and have a look at the Zeeland

bridge near Zierikzee from time to time.

When there's a big storm, I make films

to see how the blocks respond.’