DELTARES, FEBRUARY 2015

23

22

M

any managers of subsurface infrastructure

face the same problem: steel pipes that are

eaten away by bacteria, with leaks occurring

incredibly quickly. This is known as ‘microbial

corrosion’ (MIC). MIC can lead to extensive damage and

network operators would very much like to get to grips

with this widespread phenomenon. However, the process

is a complicated one and it is not easy to understand. At

present, network operators resort primarily to preventive

measures such as protective coatings, cathodic protection

systems or replacing pipes early. Worldwide, these

measures cost billions, even though it is not always clear

whether they are effective.

Deltares believes that large amounts can be saved if we

can clarify the conditions that favour MIC, how fast it

develops, and the right level of protection. That is why

we have, on behalf of a number of network operators,

been studying MIC for some time now. Working together,

we are steadily improving our understanding of this

process. Deltares can now determine, on the basis of

laboratory and field studies, where there is a risk of

MIC, how fast the process can be, and what protection

is required. This allows operators to service their

underground lines effectively and to prevent expensive,

unnecessary replacements or effective prevention

measures.

For more information:

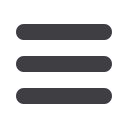

jan.gerritse@deltares.nlElectrodes measure

a range of values

- such as sulphide

levels, acidity

and oxygen - that

determine MIC.

Researcher Jan Gerritse inserts a micro-

electrode in the colony of bacteria growing

on the steel of the MIC sensor.

The data

logger sends

data from the

MIC sensor to

the computer.

One of the sensors for

measuring the ground

water parameters that

determine the MIC risk.

Groundwater from the

location being studied is

pumped into the array.

The various colours show

the sulphide levels in the

groundwater.

In the glass

column, the MIC

sensor measures

the corrosion rate

and determines the

right protection for

the steel.

A micromanipulator

turns micro-electrodes

in the colony of bacteria

to ensure that the test is

highly accurate.

MORE EFFICIENT MANAGEMENT FOR

SUBSURFACE INFRASTRUCTURE

Alliance between Deltares and industry produces innovative techniques

and creates new market opportunities for business.

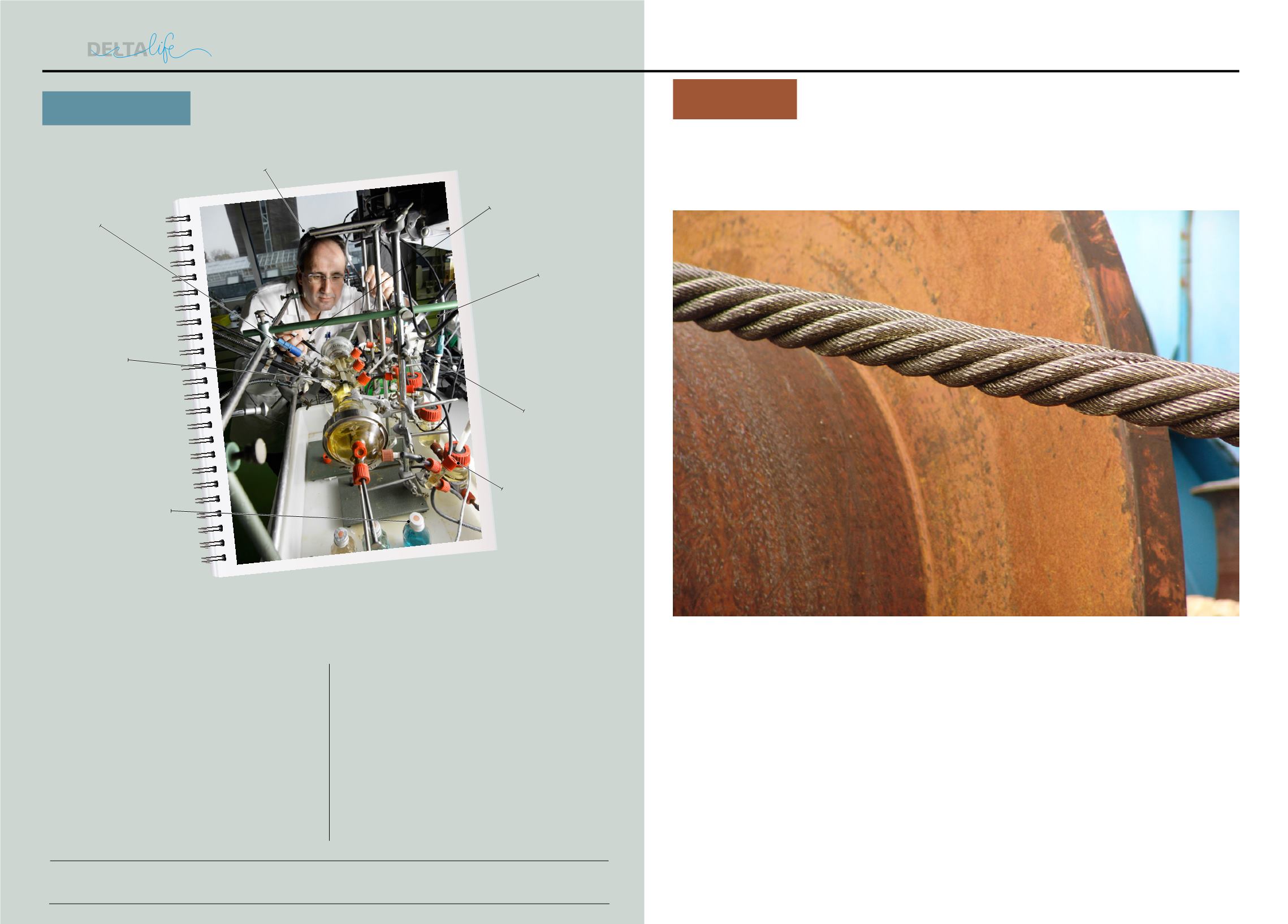

PULLING STEEL CABLES OVER THE

SEABEDWITHOUT DAMAGE

A

llseas works for oil and

gas companies, instal

ling offshore pipelines

throughout the world.

The pipeline diameters

can exceed one and a half

metres and the length varies from five

to more than a thousand kilometres.

Twelve-metre sections of pipe are wel

ded to one another on ships and then

lowered to the seabed. The landfall is

managed from the shore. Thick steel

cables pull the pipeline on land. How

ever, the cables can get warped and

damaged when they come into contact

with the seabed. In the worst-case

scenario, a cable may snap. That is

an expensive business. That is why All

seas decided they wanted to know more

about the interaction between the cable

and the seabed.

Jeroen Breukels (head of the inno-

vations unit at Allseas): ‘Steel cables

that are being pulled across the seabed

behave in complex ways. They can

warp and get damaged in a range of

ways, depending on the type of cable

and the specific circumstances. The

question is whether they will then

have enough tensile strength to get

the job done. When a cable breaks, the

entire operation shuts down for a few

days. So that’s something you want

to avoid and that means you need a

clear understanding of how the cable

behaves.

Because we didn’t have that sort of

knowledge ourselves, we went looking

for a knowledge partner who had to be

familiar with the theory but also able

to conduct full-scale tests of the study

results. So it didn’t take long before we

decided to team up with Deltares. The

combination of high-level knowledge

and the testing facilities was just what

we needed. The test produced both

predictable and surprising results. All

in all, we understand the process better

now.’

TESTING GROUND

KNOWLEDGE

IN OPERATION

In the Environmental Laboratory, Deltares studies microbiological and chemical

processes that occur naturally in soil and water.